Primary Crusher - 4 Types and Usage

A primary crusher converts shot rock into usable products. Crushing reduces large rocks into small pieces. In fact it is also employed to convert rocks into fines remain. A primary crusher is only employed in crushing in some operations. Along with a tertiary crusher along with a primary crusher are utilized together in other operations.

What are the different types of primary(primaria) crushers? Autogenous crushers, gyratory crushers, jaw crushers, and impact crushers. There are numerous similarities inside the job they are doing. All of these primary crushers reduce rocks to more manageable sizes.

Listed here are the various kinds of primary crushers and their uses.

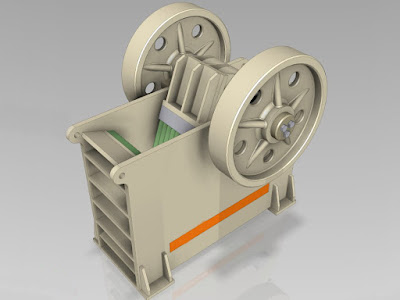

1. Jaw Crusher

A jaw crusher has two metal surfaces. This crusher uses these surfaces to squeeze rock between. One surface opens and closes such as a jaw. Rocks enter this crusher in the top. You will discover a narrow opening towards the bottom in the jaw. Rocks, which can be bigger than this opening, lodge between the two metal surfaces.

The movable jaw opens and closes from the fixed jaw. The opening and closing action decrease the rocks that happen to be lodged between the two metal surfaces. These rocks are reduced until they may be sufficiently small to fall through the narrow opening at the end on this crusher.

2. A Gyratory Crusher

Additionally, it breaks rocks. It squeezes rocks between an eccentrically gyrating spindle. Enclosing concave hopper as well as a wear-resistant mantle(manto resistente al desgaste) covers this spindle. The rock enters gyratory crusher from the top. The rock becomes wedged. And the mantle and hopper squeeze the rock.

Big rocks are split up into small pieces first. Then, the little pieces of the rocks fall to the lower position. These small pieces are further divided into smaller pieces. This is the way a gyratory crusher fails big rocks into small pieces.

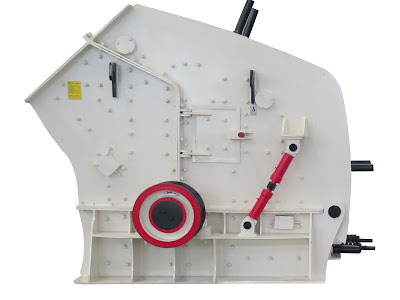

3. Impact Crusher

Impact crushers are often known as hammer mills. So how exactly does an impact crusher break a rock? It impacts the rock with hammers. The hammers swing on a rotating shaft. However, an impact crusher is just employed to break soft materials like weathered shales, gypsum, phosphate, etc.

The great news is that the impact crusher creates a finer sized product. However it cannot handle big rocks(manejar rocas grandes) as well as other large or top sized materials. This crusher is created as primary, secondary, or tertiary rotor crusher, but this is determined by the processing stage how the crusher can be used.

4. Autogenous Crusher

This crusher is designed to crush run-of-mine rock in primary crushing circuits. Autogenous crushers tend to be used for grinding and crushing. The rock, which can be being crushed, supplies the crushing force.

How is crushing accomplished within an autogenous crusher? It uses the tumbling action of the rock. And features flexible crushing circuits that process hard ores and soft ores. Also, an autogenous crusher is great for processing wet and sticky ores. This crusher is energy-efficient also it can handle abrasive ores.

These are the basic different types of primary crushers. These crushers are employed to crush rocks into small pieces. You also be aware of uses of the crushers, so choose a primary crusher that suits your job. If you want to know more about cone crusher, click here right now: www.aimixtrituradora.com/trituradora-conica/

What are the different types of primary(primaria) crushers? Autogenous crushers, gyratory crushers, jaw crushers, and impact crushers. There are numerous similarities inside the job they are doing. All of these primary crushers reduce rocks to more manageable sizes.

Listed here are the various kinds of primary crushers and their uses.

1. Jaw Crusher

A jaw crusher has two metal surfaces. This crusher uses these surfaces to squeeze rock between. One surface opens and closes such as a jaw. Rocks enter this crusher in the top. You will discover a narrow opening towards the bottom in the jaw. Rocks, which can be bigger than this opening, lodge between the two metal surfaces.

The movable jaw opens and closes from the fixed jaw. The opening and closing action decrease the rocks that happen to be lodged between the two metal surfaces. These rocks are reduced until they may be sufficiently small to fall through the narrow opening at the end on this crusher.

2. A Gyratory Crusher

Additionally, it breaks rocks. It squeezes rocks between an eccentrically gyrating spindle. Enclosing concave hopper as well as a wear-resistant mantle(manto resistente al desgaste) covers this spindle. The rock enters gyratory crusher from the top. The rock becomes wedged. And the mantle and hopper squeeze the rock.

Big rocks are split up into small pieces first. Then, the little pieces of the rocks fall to the lower position. These small pieces are further divided into smaller pieces. This is the way a gyratory crusher fails big rocks into small pieces.

3. Impact Crusher

Impact crushers are often known as hammer mills. So how exactly does an impact crusher break a rock? It impacts the rock with hammers. The hammers swing on a rotating shaft. However, an impact crusher is just employed to break soft materials like weathered shales, gypsum, phosphate, etc.

The great news is that the impact crusher creates a finer sized product. However it cannot handle big rocks(manejar rocas grandes) as well as other large or top sized materials. This crusher is created as primary, secondary, or tertiary rotor crusher, but this is determined by the processing stage how the crusher can be used.

4. Autogenous Crusher

This crusher is designed to crush run-of-mine rock in primary crushing circuits. Autogenous crushers tend to be used for grinding and crushing. The rock, which can be being crushed, supplies the crushing force.

How is crushing accomplished within an autogenous crusher? It uses the tumbling action of the rock. And features flexible crushing circuits that process hard ores and soft ores. Also, an autogenous crusher is great for processing wet and sticky ores. This crusher is energy-efficient also it can handle abrasive ores.

These are the basic different types of primary crushers. These crushers are employed to crush rocks into small pieces. You also be aware of uses of the crushers, so choose a primary crusher that suits your job. If you want to know more about cone crusher, click here right now: www.aimixtrituradora.com/trituradora-conica/

Comments

Post a Comment